Development of molds for plastic injection

Development and production of templates

Mold development is a critical step in plastic injection manufacturing, requiring expertise and precision.

We at Plastomold specialize in providing comprehensive mold development and production services,

while leveraging our deep industry knowledge to streamline the process.

We take into account various factors,

such as raw material, the way the product is extracted, the type of material input, the nature of the area, cooling mechanisms,

Sidecars, steel types, encapsulated quantity, double injection capabilities and more,

To ensure the highest quality and efficiency.

Our approach:

1. Designing templates in cooperation with the customer:

At Plastomold we work closely with our customers to develop and design molds that match the product specifications. In the planning process, we carefully analyze the product and its requirements, while adapting them to the most suitable template design, which guarantees the desired result in terms of quality, cost and benefit.

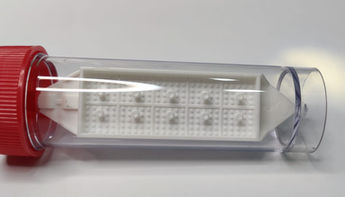

2. Advanced mold making:

We have a sophisticated mold factory located in our laboratory in Holon, as well as partnerships with reputable factories in China.

According to the customer's needs and considerations of quality, price and delivery time, we choose the most suitable production place for the production of the molds.

At each of our manufacturing sites, we ensure that all molds are manufactured to the highest standards of precision and durability.

Why choose Plastomold:

1. Expertise and experience:

With our extensive experience in mold development and manufacturing, we bring a wealth of expertise to every project. Our team of professionals is well versed in the complexities of plastic injection molding, and can provide valuable insight and recommendations to optimize your mold design.

2. Modern and sophisticated equipment:

Our mold factory is equipped with advanced machines and state-of-the-art technology to ensure the production of quality molds. We invest in the latest tools and techniques to deliver precision and efficiency, resulting in molds that meet your exact specifications.

3. Quality control:

We run a strict quality control process to ensure the quality of our molds. Each mold undergoes thorough testing to ensure its functionality, durability and compatibility with the injection process.

4. Solutions to improve cost-effectiveness:

At Plastomold we understand the importance of cost-effectiveness. We aim to provide competitive pricing without compromising on quality, helping you achieve the best return on your investment.

Choose Plastomold as your trusted partner for mold development and production.

Contact us today to discuss your project requirements, and we will turn your ideas into reality.